Facility Overview

◆TUAT Advanced Plant Factory Research FacilityTUAT Advanced Plant Factory Research Facility

Upon receiving a subsidy from the Ministry of Economy, Trade, and Industry in 2009, Tokyo University of Agriculture and Technology established an advanced plant factory research facility for fruit trees in March 2011.

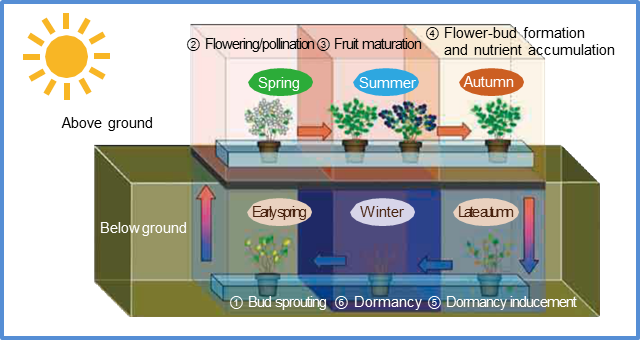

The facility features six rooms which reproduce the four seasons - spring, summer, autumn and winter as well as early spring and late fall. Above ground, natural light penetrates a glass ceiling to drive photosynthesis, while below ground, artificial lights are provided to replicate optimal environmental conditions. Blueberry pots are moved between each room, aiming to accelerate the fruiting cycle of the trees and achieve high yield with year-round production.

◆Background Information

Typically, plant factories use artificial light or natural light for growth. Artificial light plant factories mainly focus on leafy vegetable crops such as lettuce. Normally, leafy vegetables are harvested in 70-90 days when grown under natural conditions. However, if grown in an optimal environment under artificial light, crops can be harvested in as little as 40 days. Furthermore, the yield is dramatically increased when artificial light and optimal conditions are combined with dense planting in multi-stage beds. Therefore, the year-round production of lettuce is done in an artificial light type plant factory (also called “closed type”) in which the environmental parameters are controlled in a closed space. Contrasting this, tomato plants require greater light energy input than would be feasible artificially because the exhaustive processes of vegetative and reproductive growth (flower differentiation and fruit growth) occur simultaneously.

Cultivation aiming at the high yield which harvests over 25 stages in large cultivation facilities using sunlight is carried out. Natural light plant factories aim for high yields in large cultivation facilities using sunlight as well as CO2 gas and supplemental artificial light such as through high-pressure sodium lamps.

Before the establishment of the Advanced Plant Factory, there were no cases of plant factories for production of fruit trees, because yield is low relative to space requirements. Also, tree fruit may only be harvested perennially through the fruiting cycle of flower bud differentiation, dormancy, flowering and fruit ripening. Furthermore, since the harvest period is short and year-round cultivation has yet to be established, it has been said that no plant factory could be successful for economic cultivation of fruit trees.

However, producers want to develop cultivation methods for harvesting during the off-season, as some fruit trees are imported during this time. Accelerated cultivation by heating greenhouses can be performed on grapes and cherries from late December after the end of the plants’ dormancy. Although these cultivation methods can expand the range of the production period, they have not reached year-round harvests.

It is necessary for trees to experience four seasons to progress through flower bud differentiation, dormancy, flowering, and fruit ripening. Thus, if you can create greenhouses for the four seasons of “spring, summer, autumn and winter” and control the environment in each room, you can shift the flowering time and enable accelerated cultivation. If a single plant’s yearlong fruiting cycle can be shortened to six months, two harvests can be expected, doubling production from the same plant. In addition, through the use of a dwarf rootstock, the tree height may be reduced and potted plants may be more densely arranged.

Together, if year-round production and high-yield can be realized through

● shortened fruiting cycle

● dense planting using pots

● appropriate environmental control

● fertilization management

then plant factories may become an appropriate strategy for economic production of fruit.

◆Features of the Facility

The Advanced Plant Factory is housed in a two-story structure with above ground rooms utilizing natural sunlight and basement level rooms utilizing artificial light. In consideration of the life cycle of fruit trees, there were six rooms established:

Above ground,

● a spring room for flower blooming and pollination

● a summer room where fruits grow and ripen

● an autumn room for flower bud differentiation(?) and nutrient accumulation

Below ground,

● a late autumn room to induce the dormancy by the shedding of foliage

● a winter room with low temperatures for dormancy

● an early spring room where dormant buds sprout

Together, the two levels reproduce the four seasons across the six climate-controlled rooms, and blueberry pots are moved between these rooms, accelerating their fruiting cycle. Through this, safety has been improved, high-quality fruit yield has been increased, and the research facility can maintain year-round production.

【Facility features】

*Two-story structure comprising a ground floor and underground floor

*Six cultivation rooms that reproduce the seasonal climate conditions

*Equipment for automation system research

*Energy saving by installing solar panels, etc.

*“Visualized” energy balance(?)

*Training rooms

【Research elements】

* Halved fruiting time using pot cultivation

*Improve productivity through advanced management of cultivation environment

*Improve quality of functional ingredients, etc.

*Image analysis system of pests, diseases and disorders

*Tree health management systems

*Automated system using IC tags

11.png)