SUPERSONIC MICROJET

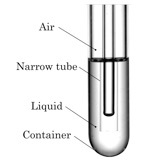

We have discovered the phenomenon that produces a supersonic microjet. This jet has a focused shape (see figure) and can reach a maximum velocity of 850 m/s (Mach higher than 2, diameter less than 10 µm). This velocity is unique for a micro-sized jet. We have studied this jet and elucidated its fluid mechanistic mechanism. This microjet has a high reproducibility and is attracting attention from various fields for its potential application as a needle-free injector and a micro cleaning device.

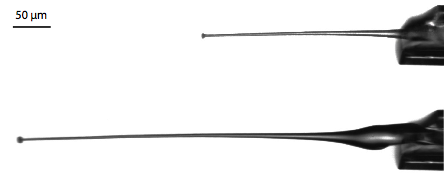

Fig.Supersonic microjet (Tagawa et al., Physical Review X, 2012). The jet generated in a 50 µm capillary tube travels at a supersonic speeds of higher than 340 m/s. It is smaller than the proboscis of a mosquito. The diameter of the jet is smaller than a mosquito's proboscis, making it suitable for various applications.

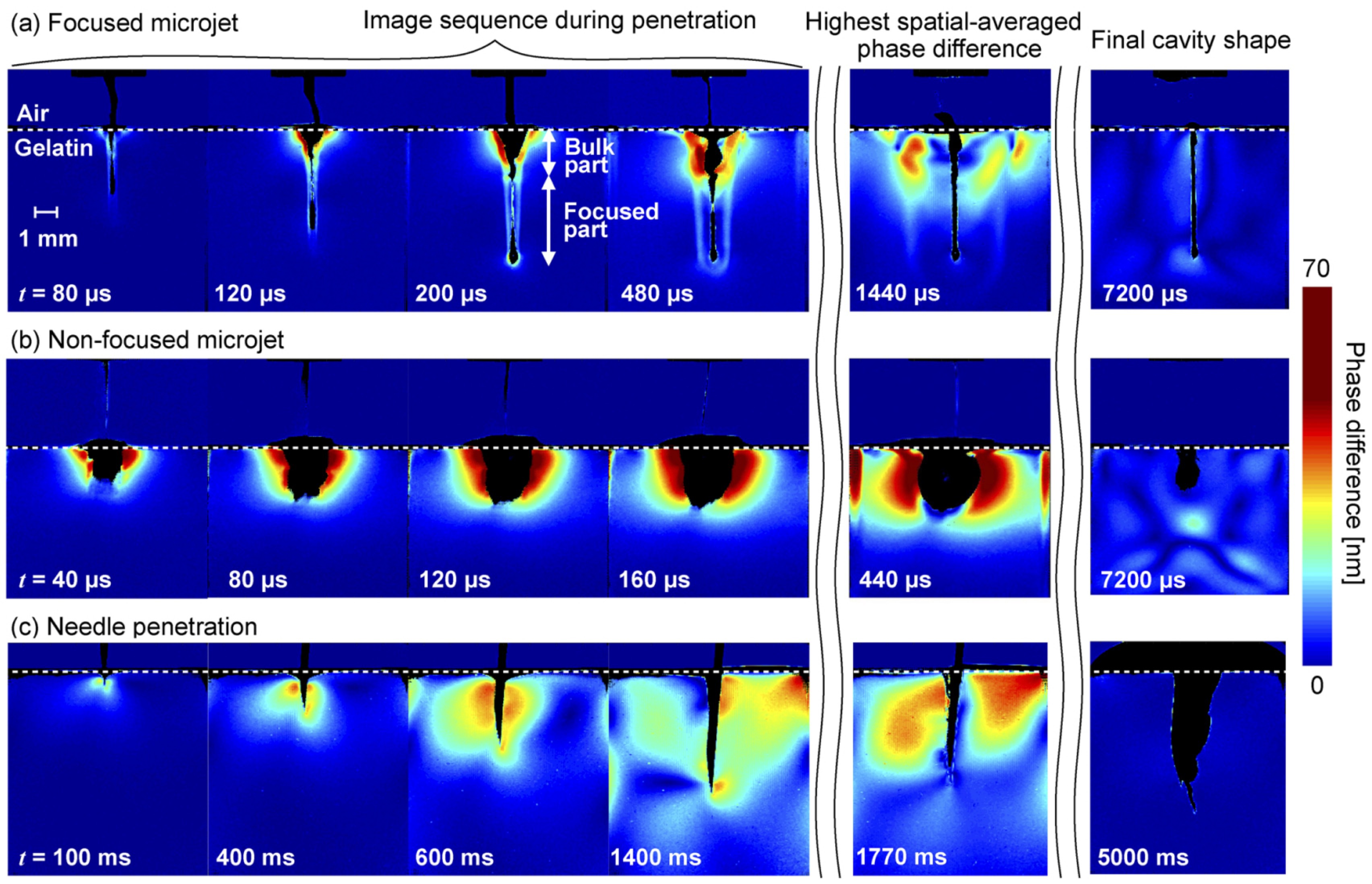

Development of a novel needle-free injector

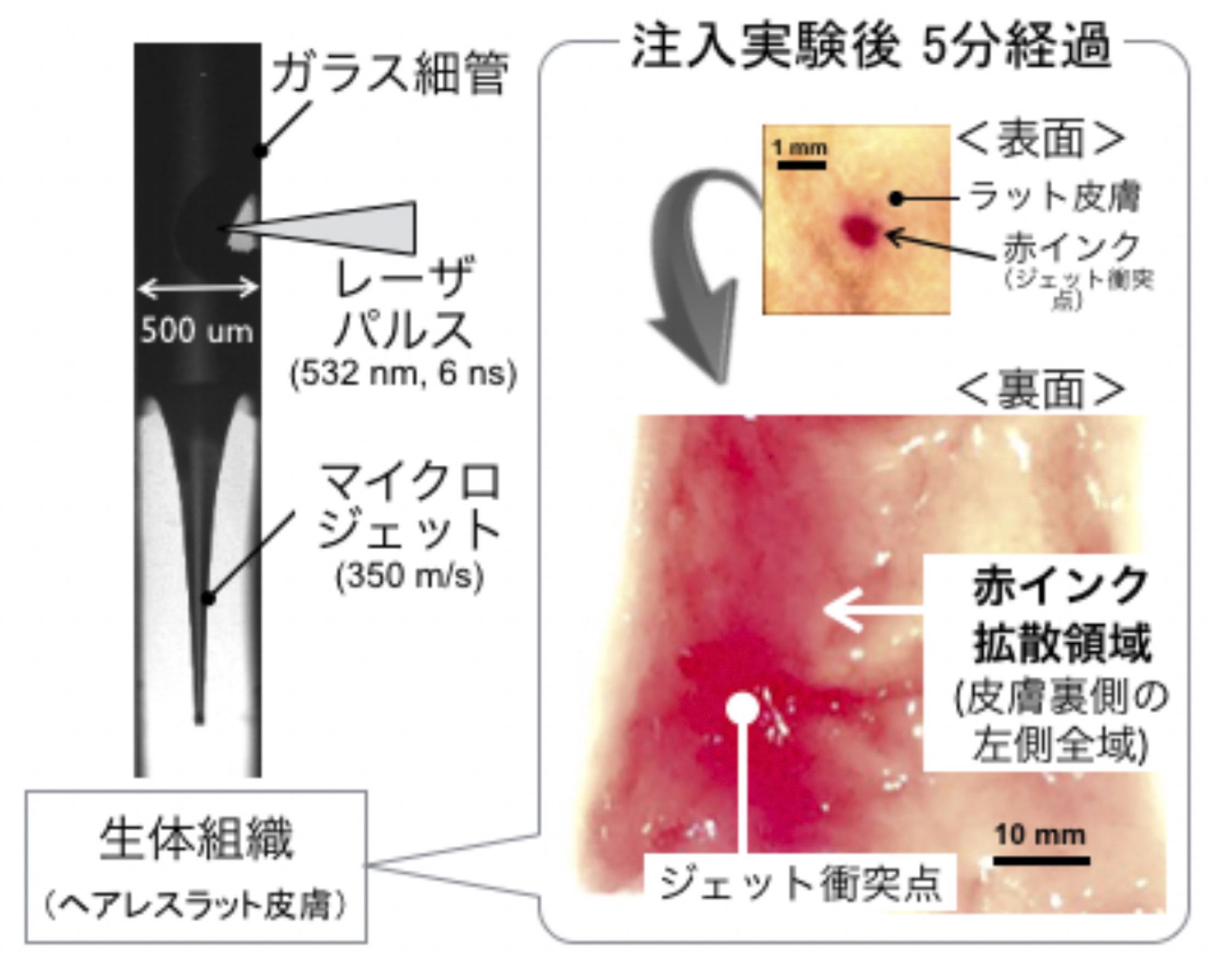

Needle-free injectors are minimally invasive devices that are expected to reduce problems related to needle injectors such as needlestick injury and trypanophobia. By using the focused microjet developed in our laboratory for needle-free injection, it has become evident that an injection can be performed with significantly less force to the injection target than a conventional needle-free injector (see figure). In collaboration with faculty members of the Faculty of Agriculture, we have also successfully performed a needle-free injection through rat skin using the focused microjet (see figure).

Fig. Distribution of the force generated during needle-free injection of the focused microJet. It was found that the generated force was lower than that of needle injection and conventional needle-free injectors (Miyazaki et al., Scientific Reports, 2021).

Fig. Injection of a focused jet of red chemical solution into rat skin. The possibility of penetration through the skin has been confirmed (Kiyama et al., Journal of Visualization, 2019).

VISCOUS LIQUID MICROJET

We developed a device capable of ejecting highly viscous liquid (10,000 times more viscous than water) in the form of jet (see figure). This device has a very simple mechanism, so it is expected to have smaller size and lower cost than existing devices. This achievement enables the ejection of highly viscous liquids, which has been difficult with conventional technology, and is highly anticipated to be applied in various technology fields, including inkjet printing, needle-free injection, and metal wiring. The results of this research have been presented at tech conferences, such as Innovation Japan and other events (click here for poster materials, in Japanese).

Fig. (Left) Viscous microjet ejection system and (Right, courtesy of NAC Image Technology) example of highly viscous microjet ejection for manicure.

THREE-DIMENSIONAL STRESS MEASUREMENT

Fluids and solids move under the influence of forces (stress). We are developing a novel method to measure three-dimensional stress distribution from images. This method is anticipated to greatly contribute to the development of medical engineering because it allows us to measure the stress acting on human body, such as during injection and the blood flow through an aneurysm.

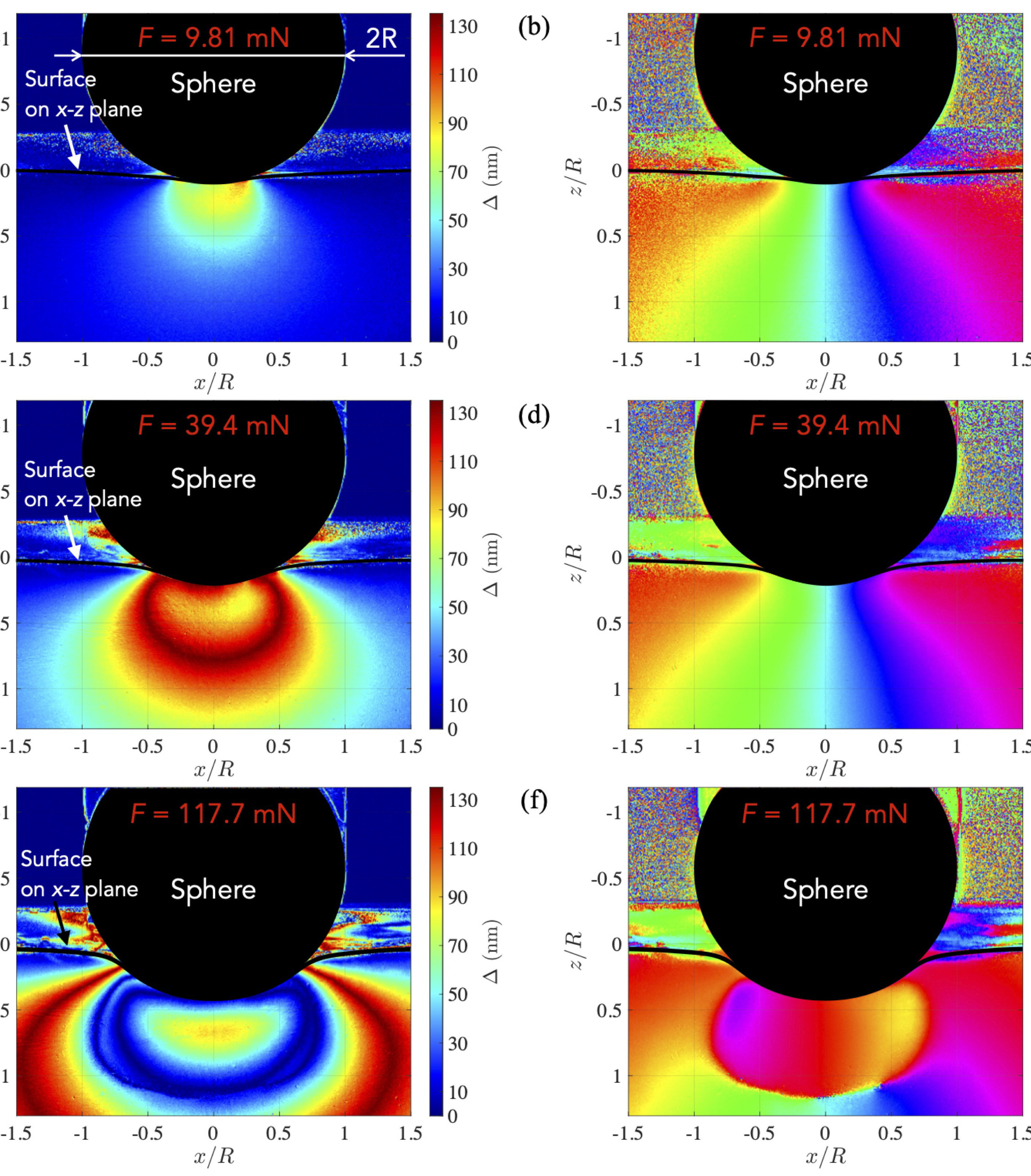

Fig. Measurement of force distribution in a gel when a solid sphere is pressed against a block of soft gel (Yokoyama et al., SSRN, 2022).

Stress field measurement using photoelasticity

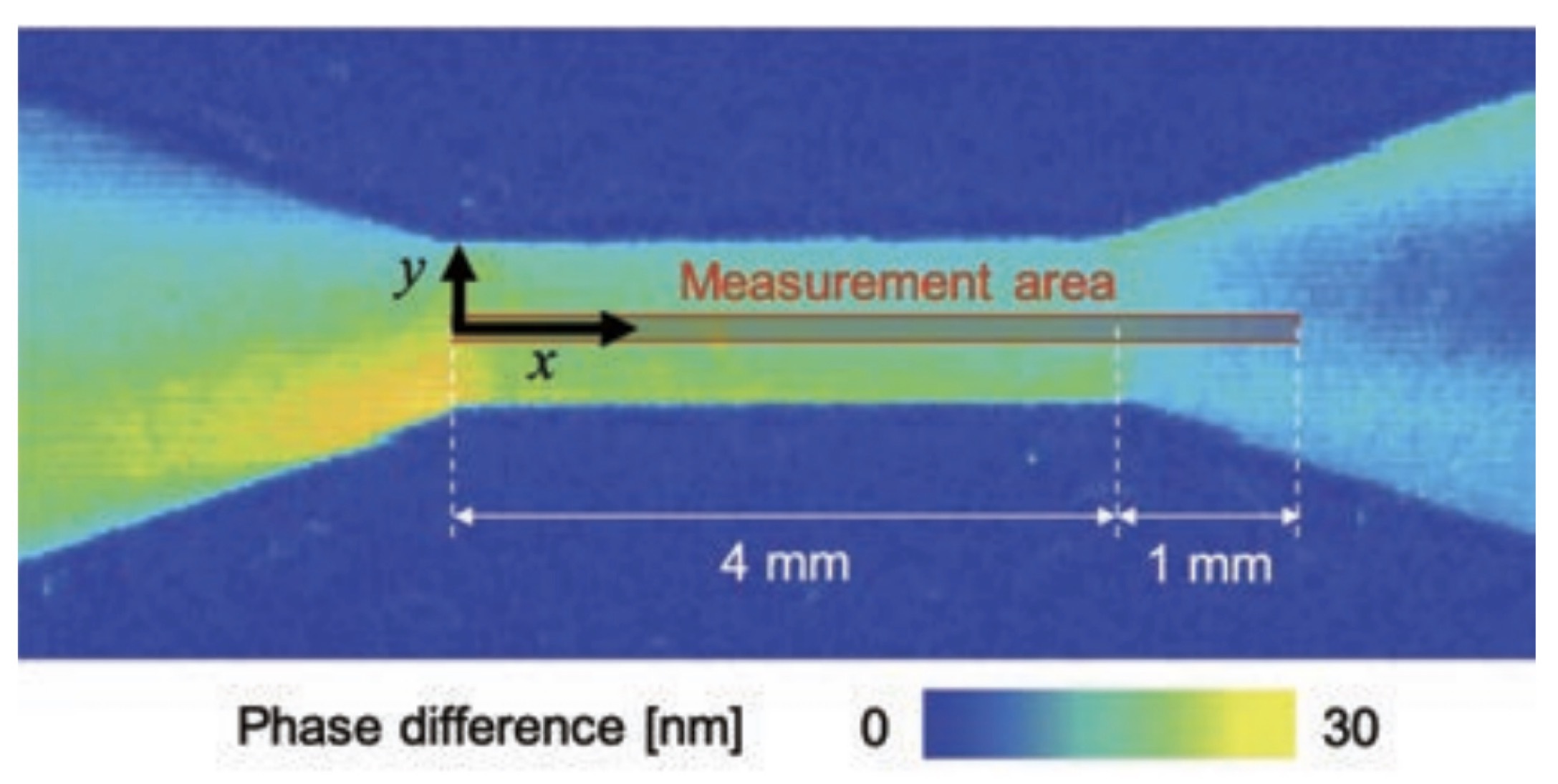

We have developed a photoelastic technique to measure the distribution of forces inside a fluid. We have successfully visualized the stress distribution in a channel flow (see figure). This technique has the potential to be applied for the preliminary diagnosis of aneurysm rupture based on the distribution of forces in blood flow.

Fig. Measurement of force distribution generated when fluid flows in a channel (Muto et al., Nagare, 2019)

UNDERWATER SHOCK WAVE,CAVITATION,PRESSURE FIELD MEASUREMENT

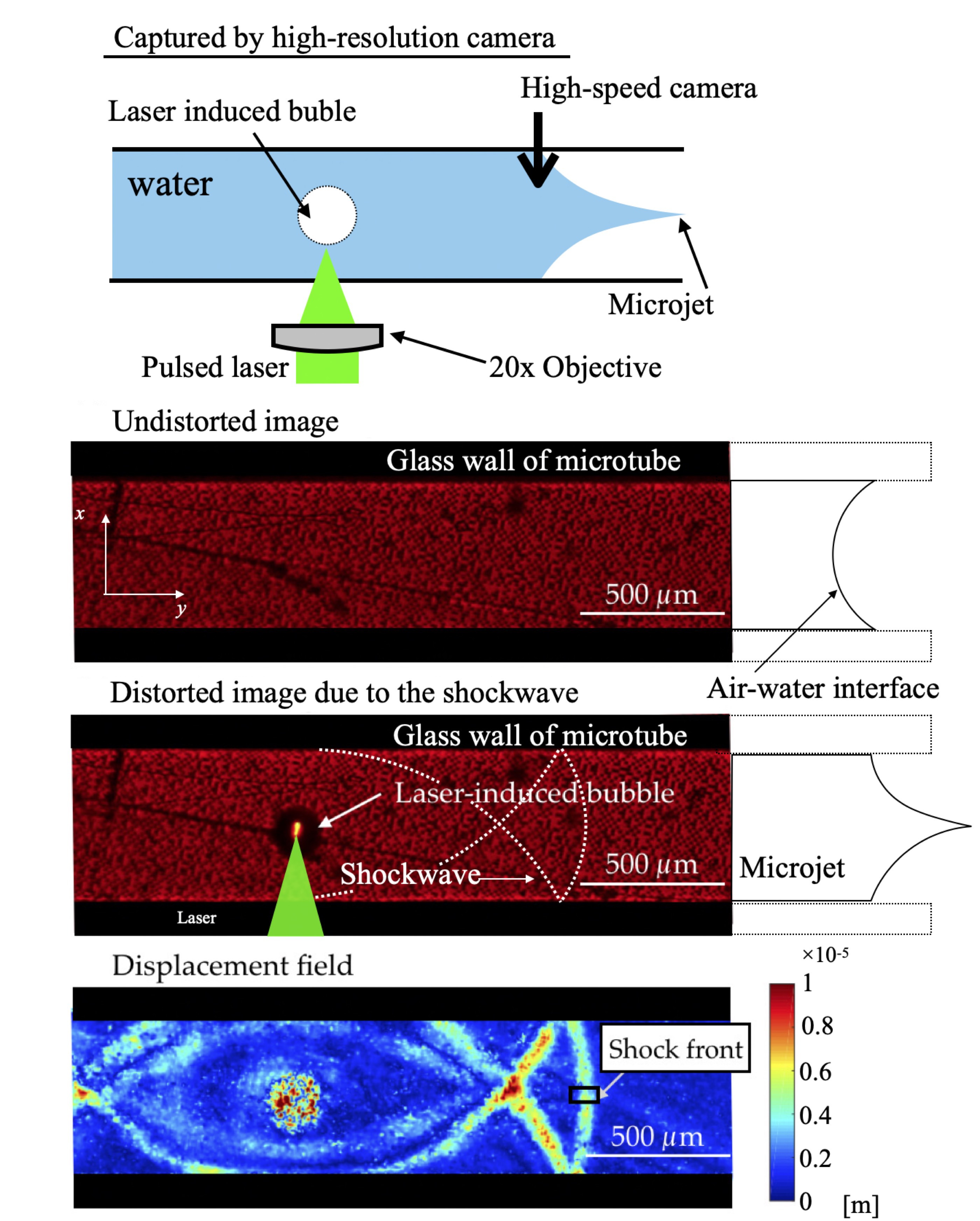

When a supersonic microjet is ejected, shock waves will travel through the liquid. We have successfully calculated the pressure distribution from an instantaneous image of the shock wave (see figure). This technique can also be applied to measure shock waves in the air and temperature changes in a medium.

Fig. Image measurement of underwater shock waves travelling in a capillary tube (Yamamoto et al., Experiments in Fluids, 2022).

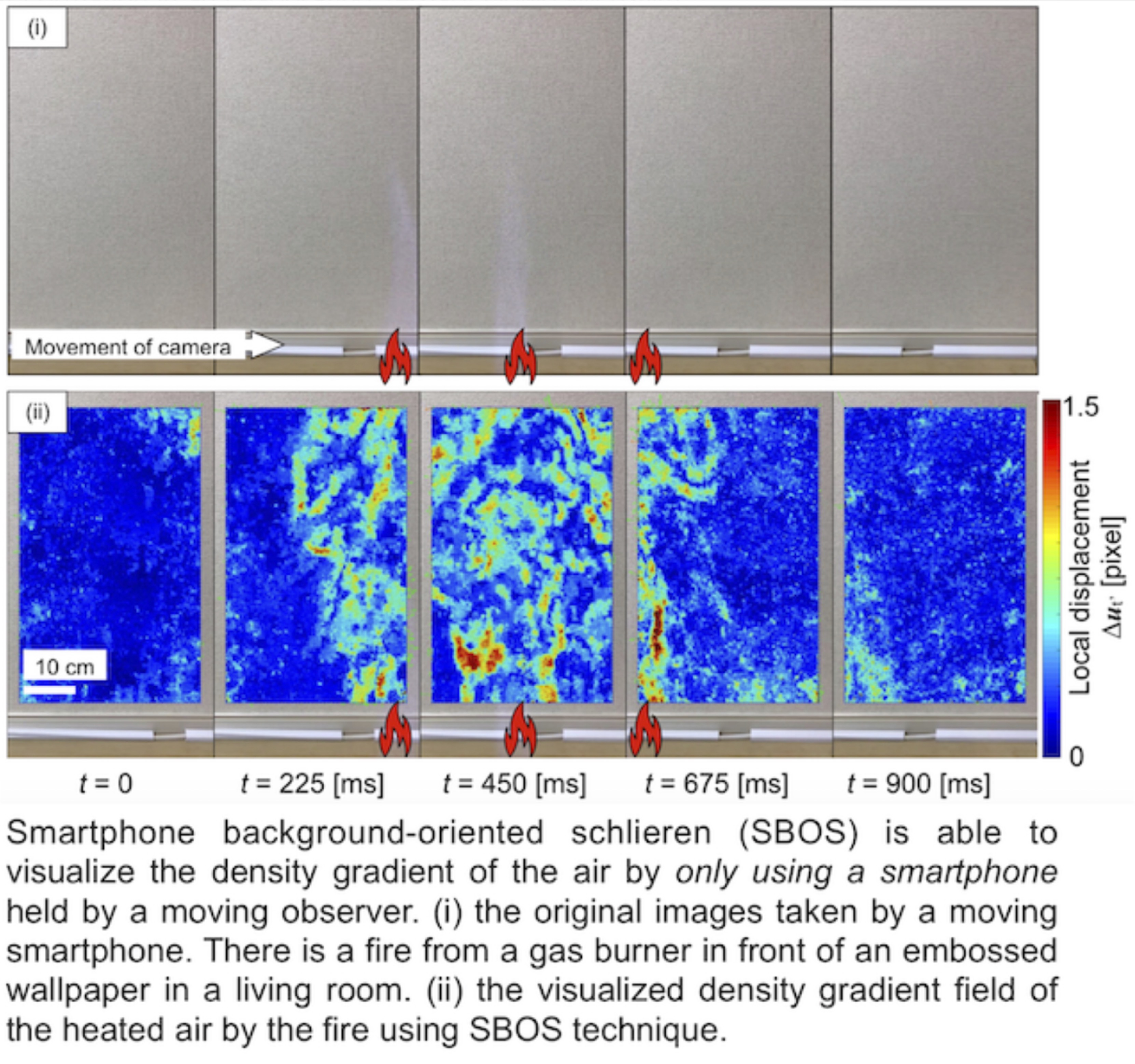

Background-Oriented Schlieren (BOS)

The background-oriented schlieren me (BOS) technique has been developed to measure pressure and temperature changes in fluids. The advantage of this technique is the simplicity of the measurement device, which can be used with a smartphone camera (see figure). Research is still ongoing to further expand the potential of this technique for the measurement of various fluid phenomena.

Fig. Temperature change in air measured by the BOS technique using a smartphone camera (Hayasaka et al., Experiments in Fluids, 2019)

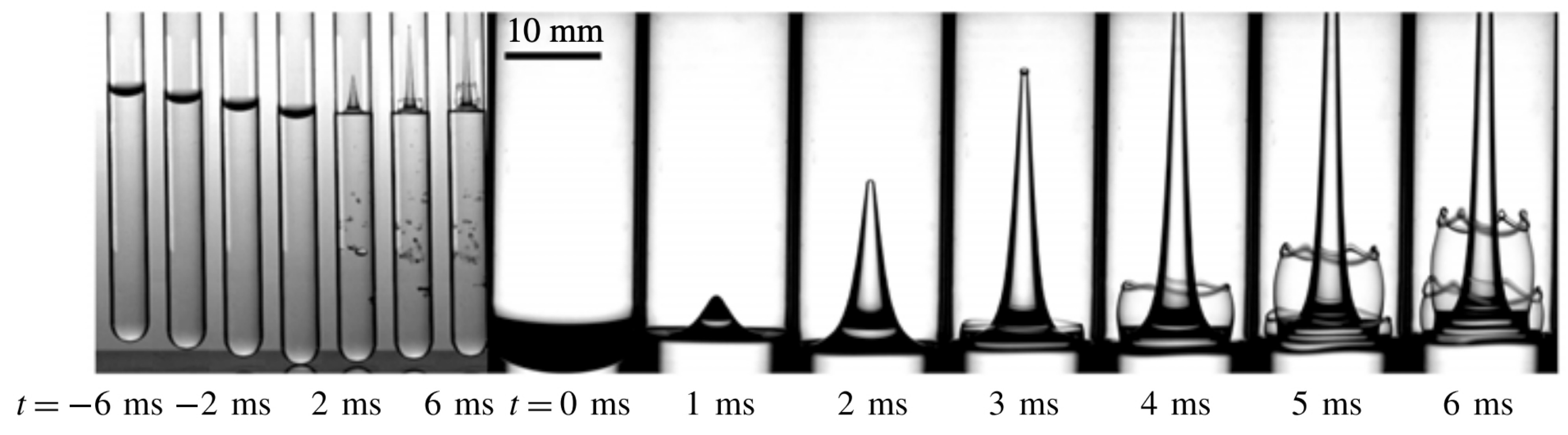

Impulse-induced jet, cavitation

We have been researching on how to eject liquid jets using the simplest possible mechanism and have invented a method of ejecting jets by applying slight impulse to the container. We discovered that when cavitation occurs in the container, the jet velocity increases by a factor of two. This phenomenon enables more efficient jetting and shows new possibilities for the use of cavitation.

Fig. Jet during cavitation (from Kiyama et al., Journal of Fluid Mechanics, 2016)

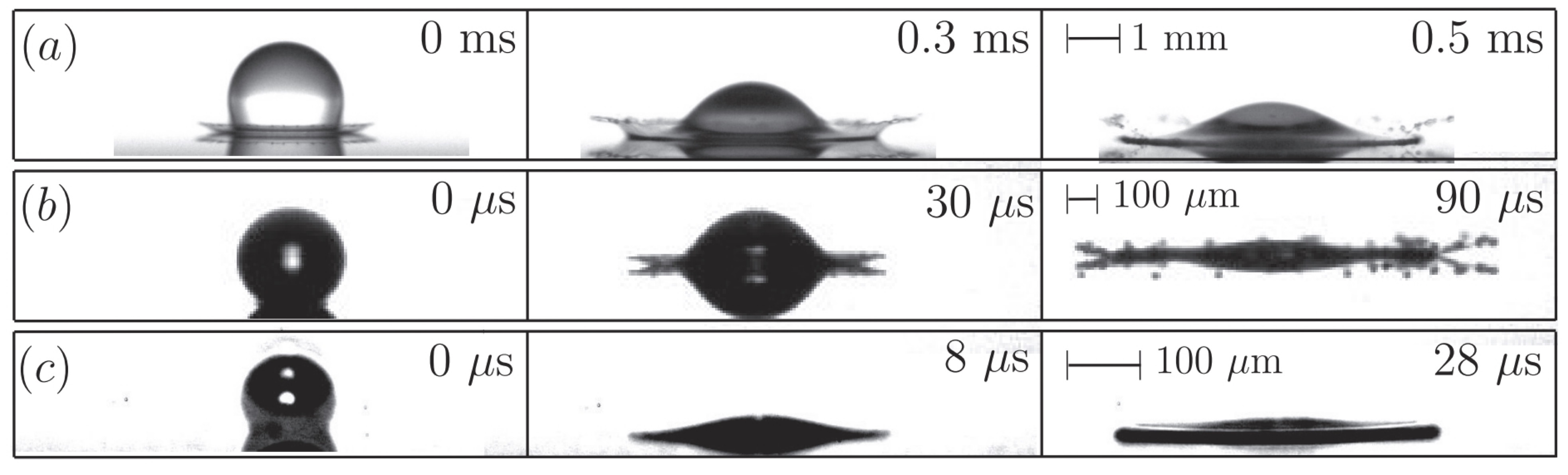

DROPLET IMPACT

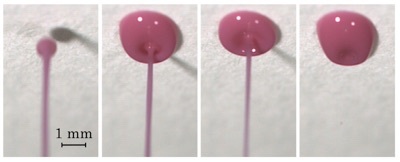

When a droplet impacts a solid wall, the droplet may either spread or splash. In the case of a milli-droplet, the droplet gradually splashes as the droplet impact velocity is increased, whereas in the case of a micro-droplet, the droplet does not splash as the droplet impact velocity is increased (see figure). Thus, droplet impact is a simple phenomenon with many unanswered questions. We have successfully unraveled some of these mysteries.

Fig. Droplet splashing at various impact velocities and droplet sizes (from Usawa et al., Physical Review Fluids, 2021).

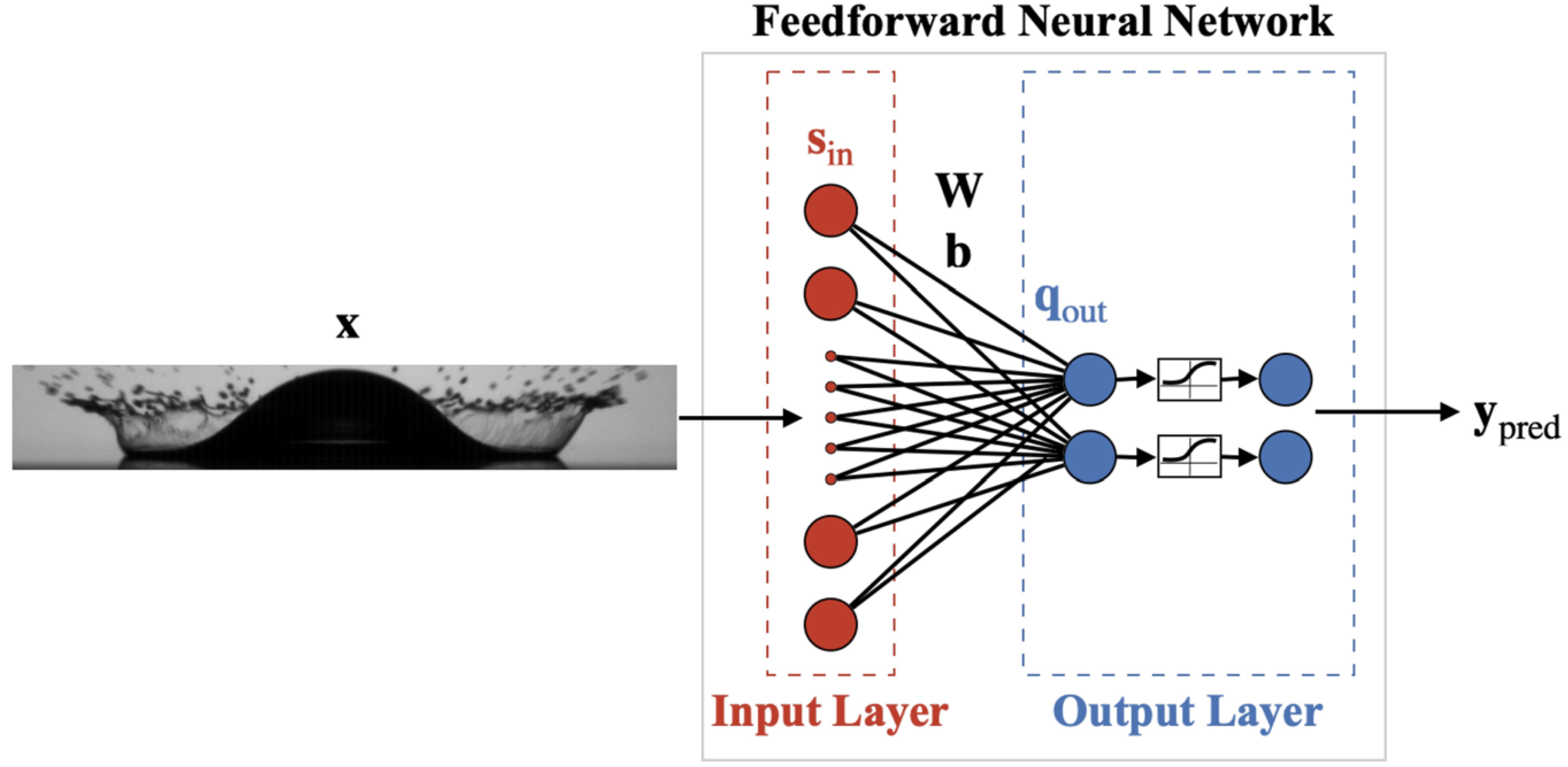

MACHINE LEARNING

Fluid phenomena are complex and have hidden features that are not noticeable to humans. Using machine learning for droplet impact phenomena, we have successfully extracted important features that were previously unnoticed (see figure). The effective use of machine learning can further accelerate fluid dynamics research.

Fig. Application of machine learning on droplet impact phenomena (Yee et al., Physics of Fluids, 2022).

LEVITATING DROPS

We discovered the phenomenon of levitating droplets on a moving surface (see Movies 1 and 2). This is an important phenomenon that can occur in inkjet printing and fire-extinguishing sprays. A thin air film of a few micrometers thick exists between the droplet and the moving wall, and the flow within this film causes the droplet to levitate. To investigate the mechanism of the levitation phenomenon, we measured the shape of the thin film in three dimensions with sub-micrometer accuracy. This phenomenon is not only important from the engineering point of view but is also a mysterious phenomenon fabricated by fluid dynamics.

Movie 1 Movie of a levitating droplet (Saito et al., APS/DFD 2014, Gallery of Fluid Motion) Hope you will enjoy this beautiful movie of a levitating droplet.

Movie 2 Movie of a levitating droplet (Sawaguchi, Hama, et al., Droplets 2015 Best Video Award)

PARTICLES IN TURBULENCE

Particles dispersed in a turbulent flow form clusters. We developed a novel method using Voronoi diagrams to analyze these clusters using a Lagrangian approach (see figure). This method allows us to perform not only Eulerian cluster analysis, but also Lagrangian analysis, which is impossible with conventional methods. This will greatly contribute to the future development of Lagrangian analysis of turbulent flows. In addition, a three-dimensional measurement system with four cameras was constructed to measure the statistical behavior of microbubbles in dynamic lattice turbulence. This enabled us to discuss not only the energy of particles in turbulence, but also the momentum. This achievement was highly rated and awarded with the Ryumon Award of the Japan Society of Fluid Mechanics (2015).

Fig. Example of a 3D Voronoi diagram (Tagawa et al., Journal of Fluid Mechanics, 2012)

SINGLE BUBBLE IN WATER

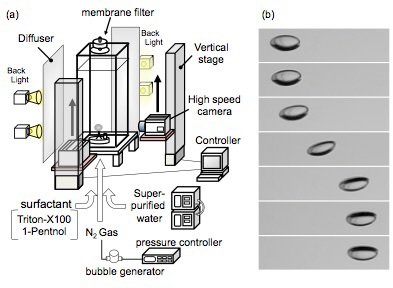

A millimeter-sized bubble rising in a stationary fluid performs three-dimensional motion such as zigzag or helical motion. This phenomenon is often observed in industry, such as water purification systems and chemical plants, thus the elucidation of the phenomenon is highly significant. A detailed three-dimensional observation on the trajectory and the shape of a bubble was performed by synchronizing two high-speed cameras and tracking bubbles on a vertical stage (Figure). We also varied the boundary condition on the bubble surface by adding a small amount of surfactant. This is the first ever study on the behavior of bubbles under intermediate boundary conditions between the free-slip condition (with slip velocity) and the non-slip condition (without slip velocity). Furthermore, the force applied to the bubble was calculated from the bubble trajectory and shape, and a phenomenon unique to surfactant was discovered.

Fig. (a) Setup of the 3D measurement system (b) Image sequence of a bubble with a diameter of 2 mm (Tagawa et al., Journal of Fluid Mechanics, 2014)