Overview

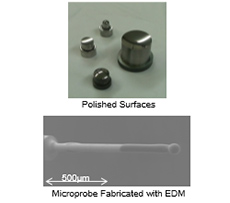

The research interest in our laboratory is mainly focused on manufacturing, especially on non-traditional machining technologies. The research topics are related with the electro-chemical machining (ECM) and electrical discharge machining (EDM) technologies for micro metallic parts no matter how hard they arse, and the polishing technology for precise molds used for mass-production of aspheric lenses.

Biography of Dr. Natsu

Dr. Wataru Natsu is currently professor emeritus and research fellow for industry-academia-government collaboration at Tokyo University of Agriculture and Technology (TUAT). Dr. Natsu obtained his bachelor and master degrees in mechanical engineering from Shanghai Jiao Tong University (SJTU), respectively in 1982 and 1987. He served as a lecturer during December 1988 and October 1990 in SJTU. After obtaining his doctor degree in mechanical systems engineering from TUAT in 1995, he had worked as a chief engineer, and then the deputy chief in the R&D division in Kuroda Precision Industries Ltd., a precision equipment manufacturer, for 7 years. Dr. Natsu's research interests are in manufacturing and machining, especially in electrochemical machining and electrical discharge machining, and management of technology (MOT). Dr. Natsu is the fellow of The Engineering Academy of Japan (EAJ), and The Japan Society for Precision Engineering (JSPE). He has served as the president of Japan Society of Electrical Machining Engineers (JSEME), and board director of JSPE and Japan MOT Society, and currently serves as auditor of JSPE and board director of JSEME.

Degree

- Dr. Eng., 3/1995, Mechanical Systems Engineering, Tokyo University of Agriculture and Technology (TUAT)

- M.S., 1/1987, Mechanical Engineering, Shanghai Jiao Tong University (SJTU)

- B.S., 7/1982, Mechanical Engineering, SJTU

Work History

- 3/2025-date: Professor Emeritus / Research Fellow for Industry-Academia-Government Collaboration, TUAT

- 7/2016-3/2025: Distinguished Professor, Mechanical Systems Engineering, TUAT

- 11/2008-6/2016: Professor, Mechanical Systems Engineering, TUAT

- 4/2005-10/2008: Associate Professor, Mechanical Systems Engineering, TUAT

- 4/2002-3/2005: Assistant Professor, Mechanical Systems Engineering, TUAT

- 4/1995-4/2002: Kuroda Precision Industries LTD. Chief Engineer (4/1998-3/2000) and Deputy Chief (4/2000-4/2002) in R&D Division.

- 12/1988-10/1990: Lecturer, Mechanical Engineering, SJTU

- 2/1987-11/1988: Research Associate, Mechanical Engineering, SJTU

- 8/1982-8/1984: Shanghai Ship and Shipping Research Institute. Assistant Engineer (8/1983-8/1984) in Manufacturing Center.

Main Service to Academic Association

- Fellow, The Engineering Academy of Japan

- Fellow, Japan Society for Precision Engineering

- Auditor, Japan Society for Precision Engineering

- Executive Board Director, Japan Society of Electrical Machining Engineers

- Editorial Board Member, International Journal of Electrical Machining

- Past Executive Board Director, Japan Society for Precision Engineering

- Past Chairman, Committee of Ethics for Engineers, Japan Society of Mechanical Engineers

- Past President, Japan Society of Electrical Machining Engineers

- Past Executive Board Director, Japan MOT Society

- Past Editorial Board Member, International Journal of Machine Tools and Manufacture

- Past Associate Editor, Precision Engineering (Journal of the International Societies for Precision Engineering and Nanotechnology)

- Past Associate Editor, Journal of Advanced Mechanical Design, Systems and Manufacturing

- Past Editor-in-Chief, Journal of Japan Society of Electrical Machining Engineers

Selected Research Topics

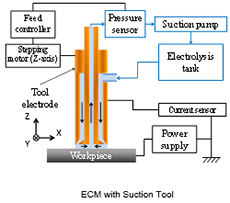

1) Research on Electrochemical Machining (ECM)

- Realization of Eco-friendly Electrochemical Micro-machining by Using Ultra-low Concentration Electrolyte

- ECM Method for Holes with Complex Internal Features by Controlling Conductive Area Ratio along Tool Electrode

- Shape Generation with Suction Tool with function of Gap-width Detection and Machining Area Confinement

- Research of Area-limited Electroplating with Suction Tool

- Study on Electrochemical Machining of Oil Pocket on Sliding Surface with Electrolyte

- Fast Fabrication of Tungsten Carbide Alloy Micro-pin with Environment-Responsive ECM

- Investigation of Machining Characteristics of Tungsten Carbide Rod by Using Electrolyte Jet Machining

- Study on effect of ECM conditions on wettability of machined surface

- Detection and Control of Gap-width with Peak Current in Pulse ECM

- Understanding ECM Phenomenon by Using Equivalent Circuit for Electrolytic Reaction

- Proposal of Pulse Power Supply with Raised Low-level Voltage for Accuracy Improvement in Wire ECM

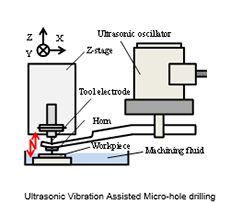

2) Research on Electrical Discharge Machining (EDM)

- Study on Influence of Electrode Material on Hole Drilling in Micro-EDM

- Improvement of Machining Characteristics of Micro-EDM with Ultrasonically Vibrated Machining Fluid under Ultra-small Discharge Energy

- Micro-Probe Fabrication Utilizing Abnormal Wear on Tool End-Surface in Micro-EDM

- Understanding Behavior of Working Fluid Movement in Micro EDM through flow analysis

3) Research on Mechanical Polishing

- Research on Surface Generation with Rotating Polishing Tool

- Fabrication of Small Polishing Tool by Using Electrophoresis Phenomenon