Spherical UltraSonic Motor Spherical UltraSonic Motor

The Spherical Ultrasonic Motor (SUSM) can rotate in 3 degree of freedom

(DOF). This is an original technology at Toyama laboratory. It has characteristic

of an Ultrasonic Motor, such as high-responsibility.

Structure and Driving principle

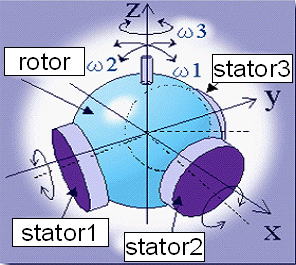

As shown in Fig.1, the SUSM is composed of a sphere and three annular stators.

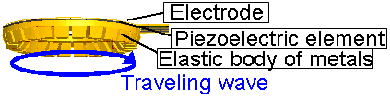

The stators (Fig.2 is the detail of this stator) hold sphere (spherical

rotor). As shown in Fig.3, the three stators produce torque around each

axis. Compositing each torque makes it possible to generate 3DOF rotation.

Rotational direction and speed can be controlled by changing the torque

at each stator.

In order to make 3DOF, generally, three electromagnetic motors are required,

and it make the structure very complicated and large. The SUSM can generate

3DOF by single actuator and it can be compact. Also this simple structure

makes miniaturization possible. We achieved the SUSM with a small diameter

of 15 mm. Fig.4 shows the movement of the SUSM controlled by a joystick.

|

Fig.1 Structure of Spherical UltraSonic Motor

Fig.2 Enlarged view of the stator

|

Fig.3 Composition of driving force from 3 stators

|

|

We are studying further about Inspection of Industrial Piping robot, using

our knowledge of the SUSM.

Industrial-piping inspection Robot

Nowadays, pipline network including water pipe, gas pipe and sewer pipe

covers the urban city, and the cost and time spent on its maintenance is

increasing greatly. For this reason, we suggest the Industrial- Piping

inspection Robot. By using this inspection tool, the cost and time spent

can be reduced remarkably.

Using the SUSM as camera acturator at the head section, the camera can

be directed anywhere, as far as 135 degrees. Because it has a joint section,

it can move through L-tube.

|

Fig.5 Inspection of industrial piping robot

Fig.6 Head section of inspection robot

|

Copyright(c)2009 Toyama laboratory. All rights reserved.

|